How should food manufacturers choose a multihead computerized combination weigher for packaging machines?

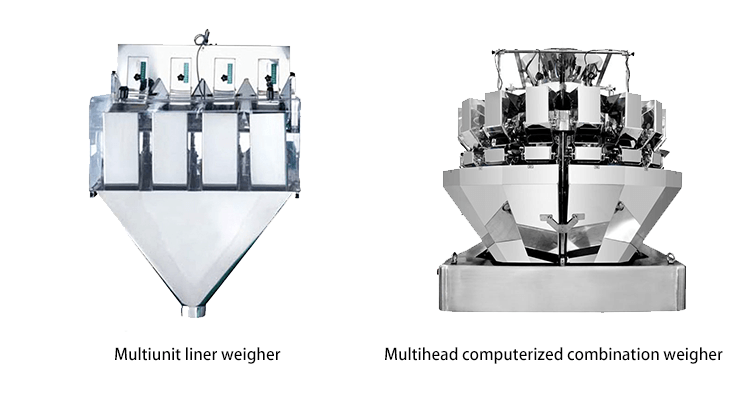

At present, there are mainly two types of multihead weighing equipment on the market:

One is a multihead computerized combination weigher, the other one is a multiunit liner weigher. Although the latter also has multiple weighing heads that can weigh different loads separately, and each weighing hopper discharges materials to the same loading device separately, this type of scale does not have a combination function. The user must distinguish it when choosing a weighing packaging machine with multihead scale, otherwise it will be very difficult. It is difficult to meet the requirements for use.

What kind of product is suitable for a packaging machine with multihead computer combination weigher?

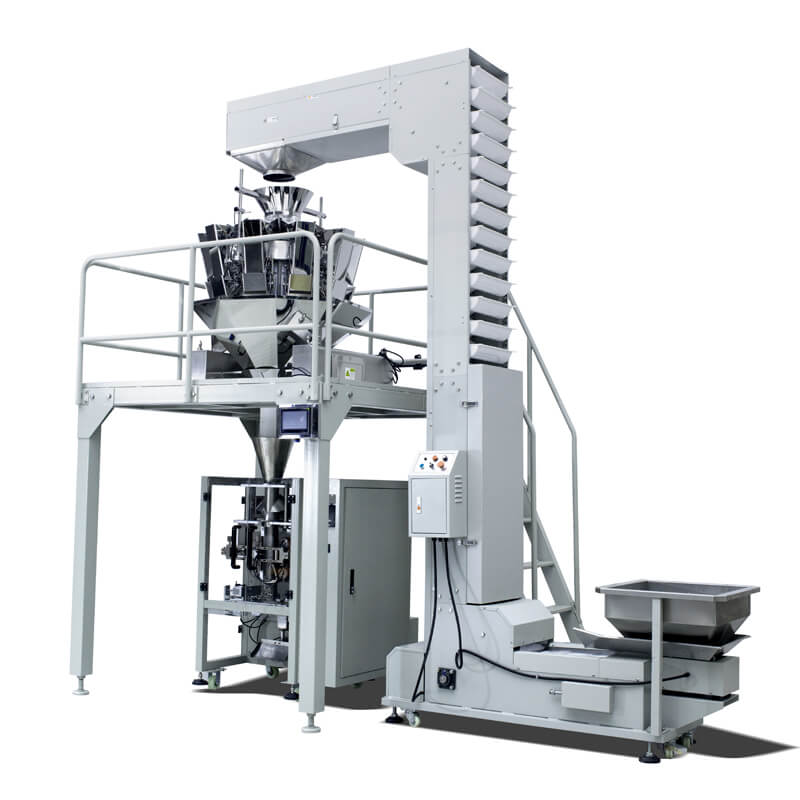

Multihead weigher is mainly used for high-speed, high-precision automatic quantitative weighing of uniform and uneven particles, regular and irregular bulk items. There are mainly the following categories of products: puffed food, candy and melon seeds, pistachios and other large-shell nuts, jelly and frozen food, snack food, pet food, plastic hardware, etc.

What aspects should users pay attention to when choosing a multi-head computerized combination weigher?

1.Accuracy requirements

In order to reduce the loss caused by multiple products when choosing a multihead scale, the user is generally willing to choose a high-precision multihead scale. Therefore, the user should understand the important allowable error requirements of the packaged food before purchasing a multihead scale.

2. Requirement of measuring speed

When users choose a multihead weigher, in order to obtain good economic benefits, while choosing high-precision equipment, fast speed is also very important. At present, the weighing speed of an ordinary domestic multihead weigher is about 60 bags/min, but the more the number of weighing heads, the faster the speed. For example, the speed of 10-head weigher is 65 bags/minute, and the speed of 14-head weigher is 120 bags/minute. At the same time, the user should also pay attention to the lifting conveyor and the packaging machine at the front and rear ends of the multihead weighing scale to complete the whole process from weighing and measuring to packaging.

3. Requirements for material specific gravity and particle size

For materials with different specific gravities, when selecting a multihead scale, because the specific gravity of the material is different, even the same weight of materials will have a large difference in volume. Therefore, the user cannot just look at the maximum combined weight of the scale when choosing a multi-head scale. Also refer to the maximum combined capacity.

Editor: Connie

Categorías

último blog

Etiquetas

© Derechos de autor: 2026 Foshan Coretamp Packaging Machinery Co., Ltd. Todos los derechos reservados.

IPv6 red compatible

Enlaces amigables :

Color Sorter